Electronic/Electrical Hardware Design & Validation Engineering

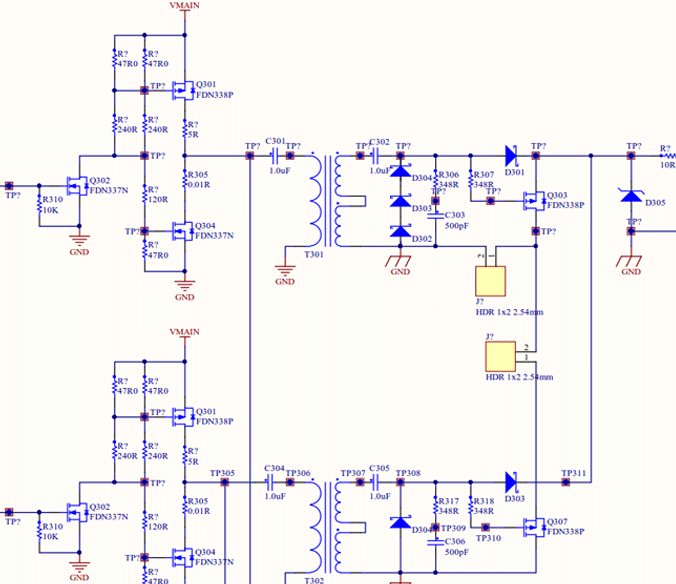

Electronic Circuit Design – Analog, Digital and Power Implementation

-

Systems Analysis and Design

Systems requirements analysis and design based on customer requirements and specifications. Cost versus performance tradeoff analysis.

-

Component Selection

Component search and selection based on performance and cost analysis.

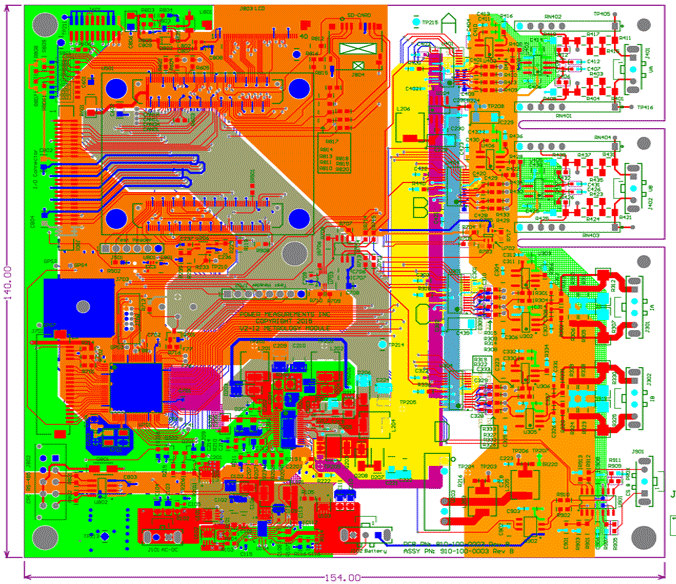

Printed Circuit Board (PCB) Development

-

PCB Design

Design rule driven placement and routing of PCBs up to 10 layers using Altium Designer. Analog, digital and mixed signal. Controlled impedance. Custom schematic component and footprint library creation when required.

-

PCB Manufacturing

Generation of complete manufacturing packages including Gerber files, drill files, pick and place, 3D step models and Bills of Material with full sourcing information.

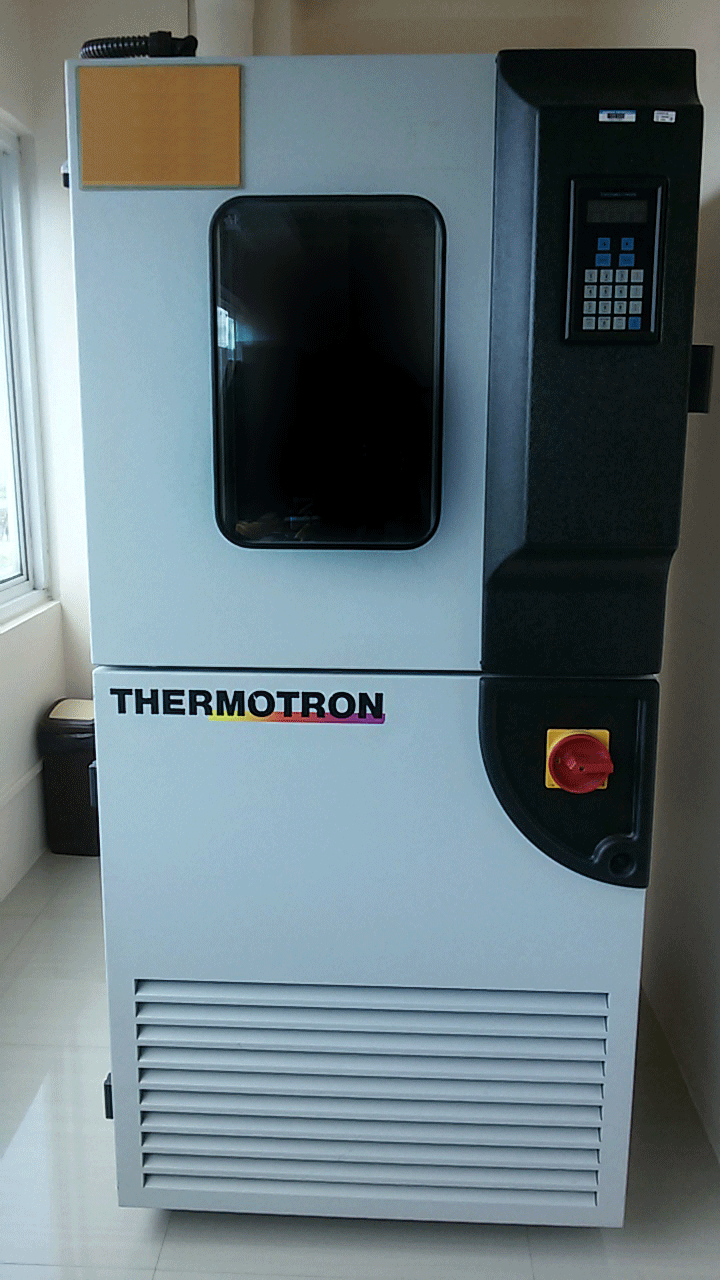

Prototype / Full Product Validation

This is part of the research and development activities that focuses on the development side that checks an engineering sample as to conform on specified functional requirements by applying functional validation in various forms of test scenarios.

Electro-Magnetic Compatibility (EMC) Test and Environmental Test is also included in this phase